Components for the semicon

Ceramic components offer significant advantages over metal and plastic parts when used in etching reactors or wet etching equipment. They retain their full dimensional stability at high temperatures – well above 1000°c. They are extremely good electrical insulators and do not outgas in vacuum. Ceramics are inert materials and are resistant to many gases, chemicals as well as plasma. Consequently, ceramics are ideal materials for use in wafer processing equipment.

MORE INFORMATION

Ceramic components and brazed ceramic-to-metal assemblies can be used in the following semicon equipment :

- deposition & ion implant equipment

- wet spin-etch equipment

- failure-analysis equipment

- electrostatic chucks

Microcertec offer the following ceramic products :

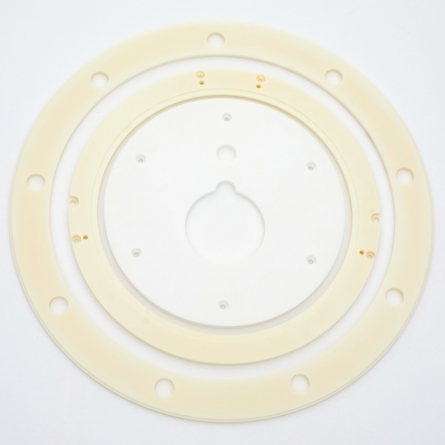

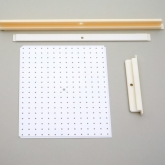

- rings, plates, frames for reactors

- high-voltage insulators

- end-effectors

- lifting pins & guides

- heating plates

- insulating plates for E-chuckc

The most commonly used ceramic materials are :

- Alumina – 94 to 99.8 % (aluminium oxide)

- Aluminium nitride (AlN)

- Silicon carbide – sintered and CVD (SiC)

- Boron nitride (Bn)

- Macor ®

- Quartz

- Sapphire

All materials