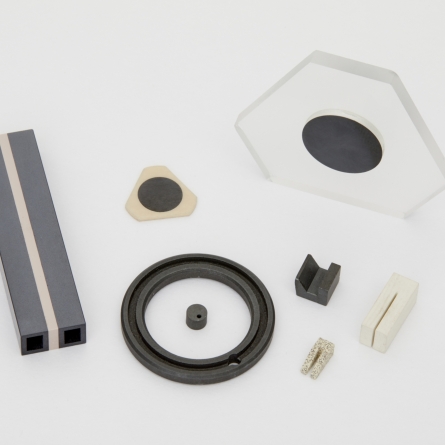

Components for the microelectronics

Advanced ceramics offer significant advantages over metals and plastics for use in the microelectronics. Ceramics are considered for their high electrical insulation, full dimensional stability at high temperatures, no outgasing in vacuum and UHV environment, and resistance to temperature variations. Finally, the majority of ceramics show high thermal insulating properties but conversly a few of them offer high thermal dissipation. Using vacuum thin-film sputtering technologies, Microcertec can offer ceramic carriers with electrical patterns on which customers will be able to bond or braze. And glass-to-metal and ceramic-to-metal capabilities are also available with Microcertec so that hermetic assemblies such as microelectronic packages and electrcial feedthroughs can be offered to customers.

MORE INFORMATION

Ceramic components and microelectronic packages are used in the following applications :

- 3D interconnect devices

- packaging - 3D, 3DMID, CI3D

- RF & HF components - circulators, phase shifters...

- HF modules for antennas

- sensors

- ceramic packages

Advanced ceramics will make it possible to manufacture the following products :

- insulators

- heat sinks

- 3D interconnect carriers

- substrates - bare and metallized

- loads, absorbers, dielectrics ferrites

- post-firing grinding of ceramic co-fired packages : achievement of a few-micron flatness on die area

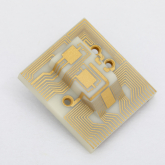

Microcertec also offer custom-made hermetic packages :

- microelectronic packages with glass-to-metal feedthroughs

- low-weight packages with high thermal dissipation base

Technical ceramics used for microelectronics applications are typicaly :

- alumina - or aluminium oxide - 94 to 99.8 %

- aluminium nitride - AlN

- quartz, glass, Macor ®

- ferrites, dielectrics, magnets

All materials

In addition to be precision ground those ceramics can be metallized with vacuum thin-film sputtering.

For bonding or brazing your components, Microcertec can offer you the following thin-film metallizing :

- titanium - platinum - gold

- chromium - nickel - gold, NiCr-gold

- copper, aluminium, silver, indium, gold-tin

These coatings have the distinction to be applied on three-dimensional parts and be subsequently etched by laser micro-machining in order to create electrical patterns or electrical insulation pads.