Zirconia (ZrO2)

Zirconia grades are various. They differentiate from each other by the nature of the stabilising agent which is used. In its pure form, zirconia is not stable. Magnesia-partially-stabilised zirconia (MgO-PSZ) and yttria-partially stabilised zirconia (Y-TZP) in particular offer an outstanding resistance to mechanical shocks as well as to flexural load, because of their high fracture toughness and relative “ elasticity ”. These two zirconias are advanced ceramics of choice for severe mechanical applications. Other grades in fully stabilised composition exist and are mostly used for high-temperature applications.

MORE INFORMATION

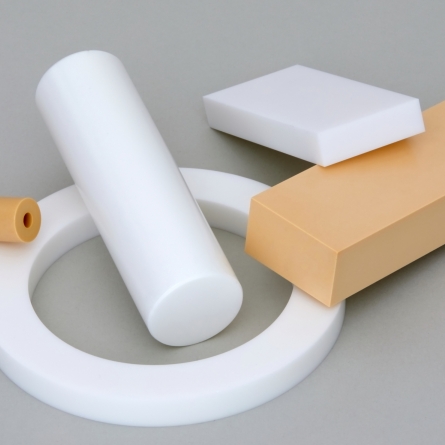

Microcertec offers those two types of zirconias that are mostly requested on the market, in pressed and extruded grades :

- magnesia-partially-stabilised zirconia (MgO-PSZ)

- yttria-partially-stabilised zirconia (Y-TZP)

MgO-PSZ and Y-TZP zirconias have the following features :

- high density

- high flexural strength (> 500 MPa for MgO-PSZ and > 800 MPa for Y-TZP)

- very high fracture toughness

- good wear resistance

- low thermal conductivity (10 x less than alumina)

- good resistance to thermal shocks

- resistance to chemical attacks

- electrical conductivity at high temperature

- fine surface finish easily achievable

MgO-PSZ and Y-TZP zirconias are advanced ceramic materials that are widely used in the following applications :

- plungers and valves for dosing pumps (food, medical, pharmaceutical industries)

- tube and ring faces for mechanical seals

- wear parts for mechanical processing equipment

- components for metrology equipment

- pins & guides for handling devices for FPD glass sheets in coating machines