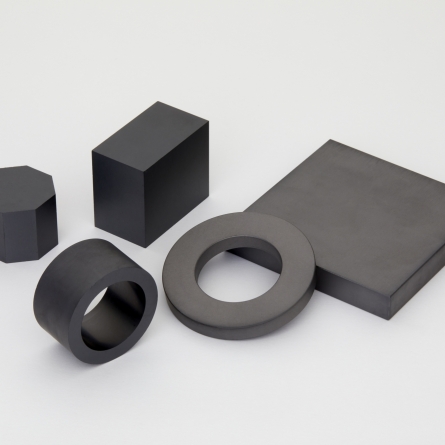

Silicon carbide (SiC)

Silicon carbide can be made in different chemical compositions. It can be found either as lower purity grades mostly used for thermal applications or high-purity grades (sintered SiC and CVD SiC) that makes silicon carbide an advanced ceramic with exceptionnal mechanical and thermal properties.

MORE INFORMATION

Microcertec offers two high-purity silicon carbide grades that are particularly suited for hostile environments :

- sintered silicon carbide

- CVD silicon carbide

Both SiC materials are mainly designed to be used in thermal-mechanical or corrosion-resistance applications because they show an outstanding behaviour to resist to wear, thermal shocks and corrosion (liquids and gases). Moreover, these pure SiC grades offer a high thermal conductivity, in the range of 120 to 160 W/m.K for sintered silicon carbide and 250 W/m.K for CVD SiC.

Sintered silicon carbide and CVC SiC have the following properties :

- low density

- excellent thermal shock resistance

- excellent wear resistance

- excellent corrosion resistance (liquids and gas)

- low coefficient of thermal expansion

- high thermal conductivity

- electrical conductivity

Sintered silicon carbide is a ceramic material widely used in the following applications :

- tube and ring faces for mechanical seals

- pump and valve components

- wafer end-effectors and chuck or heat plates for semicon processing equipment