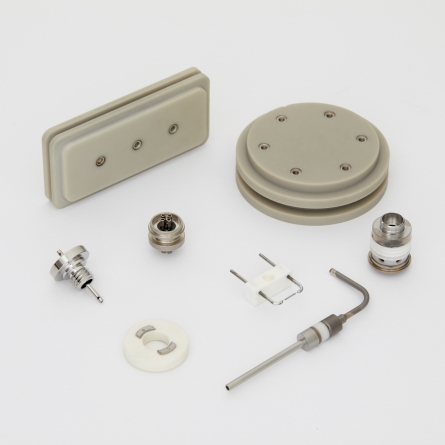

Ceramic to metal brazed assemblies

Various methods of assembly exist to bind ceramic to metal. When it comes to make an assembly that can resist to mechanical stresses and/or high temperatures, be vacuum leak tight and withstand corrosive environment, high temperature braze sealing is essential.

MORE INFORMATION

Ceramic-to-metal brazed assemblies are particularly suited for use in such severe environments as, for instance :

- airborne electronics for the aerospace - civilian and military,

- defense devices,

- medical and analytical instruments,

- high-energy physics, high and very high vacuum,

- energy industry.

The product range is not restricted to the here below list since the company mainly manufactures customized ceramic to metal brazed assemblies. For instance :

- high-voltage feedthroughs for the mass spectrometry, ion guns...

- high-voltage and/or high-pressure and/or high-temperature hermetic connectors for the energy industry..

- high-voltage brazed assemblies for electron tubes..

- hermetic feedthroughs for airborne sensors

Not all technical ceramics can be brazed. Those that are suited for brazing are mainly :

- aluminium oxide (alumina)

- sapphire and ruby

- and to a lesser extent, aluminium nitride, zirconia and silicon nitride.

The metal that is directly joined to the ceramic must have a close coefficient of thermal expansion so that the risk of residual stress in the seal that would lead to rupture is minimized. Nickel-iron alloys - Kovar, FN48, FN52… - and titanium are best suited.

But it is also possible to design ceramic-to-metal brazed assemblies using stainless steel, molybdenum, tungsten, niobium, platinum…

All materials