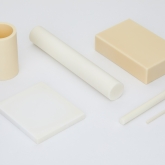

Alumina (Al2o3)

A wide variety of purity grades of alumina (or aluminium oxyde) are available on the market. Typical grades that are used for modern industrial applications are of high purity (> 95%). Amongst the various advanced ceramics that exist today, alumina is the most commonly used ceramic that has a wide range of properties and a good cost-to-performance ratio.

MORE INFORMATION

Microcertec offers a wide range of aluminium oxydes :

- pressed 94 % alumina (AL 500 - Wesgo)

- pressed & extruded 95 % alumina

- tape cast 96 % alumina (substrates)

- pressed 97,6 % alumina (AL 300 - Wesgo)

- pressed 99,5 % (AL 995 - Wesgo) - 99,8 % alumina

- extruded 99.5 % - 99,8 % alumina

- pressed 99.5 % porosity-controlled alumina (Sintox AL - Morgan) for reflector applications

- pressed 99.9 % alumina

in order to meet precisely the various requirements of our customers' applications and to optimise the manufacturing process.

Alumina is unique in having properties that offer a good mechanical-thermal-electrical insulation compromise :

- good mechanical strength under compression load

- good hardness and wear resistance

- good corrosion resistance (liquids and gas)

- good thermal stability

- excellent dielectric properties (in the range from direct currents to microwaves)

- low dielectric constant and loss tangent

- excellent bio-compatibility

Alumina is a ceramic material widely used in the following applications :

- electrical insulators and/or corrosion-resistance components for gas lasers, for semicon processing equipment (chuck, end effector, seal ring)

- reflectors / diffusing cavities for solid-state lasers (YAG) and phototherapy equipment.

- electrical insulators for electron tubes, mass spectrometers, ion detectors, laser diodes.

- structural parts for high-vacuum and/or cryogenic equipment, nuclear radiation devices, equipment used at high-temperature.

- wear and/or corrosion-resistance components, piston for pumps, valves and dosing systems, sampling blood valves.