Presentation

Our company has an experienced team whose primary objective is to ensure customer satisfaction, both in terms of responsiveness and quality.

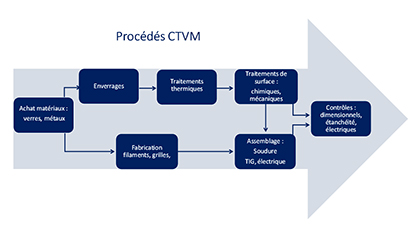

CTVM’s expertise is multifaceted : beyond our design and manufacturing know-how in glass-to-metal and ceramic-to-metal sealing, as well as filament production, we have the equipment and technical skills to integrate most of the manufacturing processes in-house.

Naturally, we also possess the expertise and the means for dimensional inspection, electrical testing, and helium leak detection in order to meet your quality requirements.

Glass-to-Metal Sealing

The principle of glass-to-metal sealing consists in creating a mechanically robust and hermetically tight bond between glass and metal, or between glass, ceramics, and metal.To achieve this type of joint, specific sealing glasses must be used — generally from the borosilicate or sodium glass families — together with metals such as Kovar, stainless steel, Inconel, molybdenum, or tungsten.

The established practice consists in combining these materials, which have different coefficients of thermal expansion. The process itself involves surface preparation of the metallic parts, positioning of the elements to be joined within graphite fixtures, heating in a furnace typically between 900 and 1000 °C, followed by a post-sealing surface treatment (polishing, nickel plating, gold plating, etc.).

The actual joining technique relies mainly on three methods:

- Matched Seal

The term “matched” refers to the matching of the thermal expansion coefficients of the different materials. The metal used in this case for the body and the pin(s) is generally Kovar, combined with a borosilicate-type glass, both having similar coefficients of thermal expansion.

Adhesion of the glass to the metal results from a chemical reaction between the glass and the oxides present on the metal surface (formed during surface preparation).

This type of sealing can also be achieved with tungsten, alumina, or molybdenum. - Compression Seal

In this second technique, the seal is obtained through compression of the metallic body — typically made of stainless steel or Inconel — around the glass bead.

This type of seal offers very high mechanical strength, even under thermal stress, and is achieved thanks to the higher coefficient of thermal expansion of the metal compared to that of the glass (usually a soda-lime glass family) whose expansion coefficient is closer to that of steel. - Mixed Seal

This configuration is typically used for multi-pin electrical feedthroughs, where the sealing of the stainless steel or Inconel body is achieved by the compression technique, while the pin-to-glass interface is produced by the matched sealing method, with the pins generally made of Kovar. In this third case, a glass bead from the sodium glass family is also used.

CTVM employs all three techniques and will assist you in designing your assembly or feedthrough to guarantee vacuum tightness down to 1 × 10⁻⁹ mbar·l/s, even after repeated thermal cycling (within the temperature limits of the glass/metal combination, of course), as well as perfect insulation between the body/skirt and the conductor(s).

Filament and Grid Manufacturing

One of CTVM’s unique areas of expertise lies in metal wire processing.

We source wires made of tungsten, iridium, platinum-iridium, tantalum, and molybdenum, and using our own proprietary techniques, we manually form filaments and grids.

Our know-how covers three main areas:

- The manufacture of small filaments made from spiral- or hairpin-shaped wires, with diameters ranging from 0.06 to 0.5 mm.

- The formation of long multi-strand and multi-material twisted filaments, several millimeters in diameter and up to over 4 meters long.

- The production of grids made from fine metal wires (≤ 0.5 mm in diameter), assembled by electric resistance welding (spot welding).

Surface Finishing

In many cases, the glass-to-metal sealing process causes surface oxidation of the metal, which requires post-treatment to protect it from corrosion and/or restore its bright appearance.At CTVM, we use two main types of surface treatment:

- Chemical etching / brightening processes, which vary depending on the metal type, the chemical agents used, and the treatment temperatures.

- Micro-bead blasting or sandblasting, applied mainly to the bodies of feedthroughs.

In addition to our in-house treatments, we can also subcontract surface finishes specified by our customers — mainly gold or tin coatings on conductors.

Welding

CTVM’s welding expertise stems from the heritage of SVT, which had developed in-house technical skills to meet diverse product requirements.Welding processes were established both to perform flange welds primarily for glass-to-metal tubular fittings (now produced and sold by COLEGLASS - www.coleglass.fr) — and Bayard-Alpert gauges as well as to weld filaments and grids.

CTVM uses two welding technologies suited to its applications:

TIG Welding

This is an arc welding process using a tungsten electrode and an inert gas shield. The electric arc forms between the electrode and the parts to be joined.

The high temperature causes the materials to melt, producing a strong, mechanically robust joint.

CTVM performs Kovar–Kovar and Kovar–Stainless steel welds, hermetically tight up to 1 × 10⁻⁹ mbar·l/s.

Resistance Welding (Spot Welding)

This electrical resistance-based welding process combines a very high electrical current, delivered through a copper electrode, with localized mechanical pressure applied by the same electrode.

No filler metal is required. Primarily used for welding fine wires, the combination of heat and pressure fuses the wires together. The resulting joint provides good mechanical strength, though hermeticity is not sought.

This process is used for welding metals such as tungsten, molybdenum, iridium, and platinum-iridium.